Dewatering plays a crucial role in the mining industry, offering numerous advantages such as decreased hydrostatic pressure, minimised legal and environmental constraints, and cost-effective drainage solutions. Over time, dewatering techniques have progressed from basic mechanical methods to sophisticated pumping systems that effectively transport water to designated containment areas.

Modern dewatering practices are capable of managing water removal in mines located several miles underground. Both underground and open-pit mining operations that extend below the groundwater level necessitate dewatered conditions to ensure safety and improve production efficiency.

Furthermore, mining companies are increasing their capital investments to promote sustainable production, with the goal of reducing their carbon footprint and adhering to ESG standards. Consequently, initiatives focused on afforestation, water conservation, and waste management are gaining prominence.

Established in 1872, Wilo has over 150 years of experience in the water pumping sector. More recently, Wilo has concentrated on creating sustainable dewatering solutions for mining operations. As a prominent manufacturer of pumps and pump systems, Wilo acknowledges the vital importance of mine dewatering pumps and recognises that each mining project has its own unique requirements, and we tailor our solutions to meet these specific needs.

Our approach prioritises intelligent, efficient, and sustainable performance, enhancing dewatering methods through digital technology and automation for better management of pumps and pump systems, thereby ensuring safe working conditions.

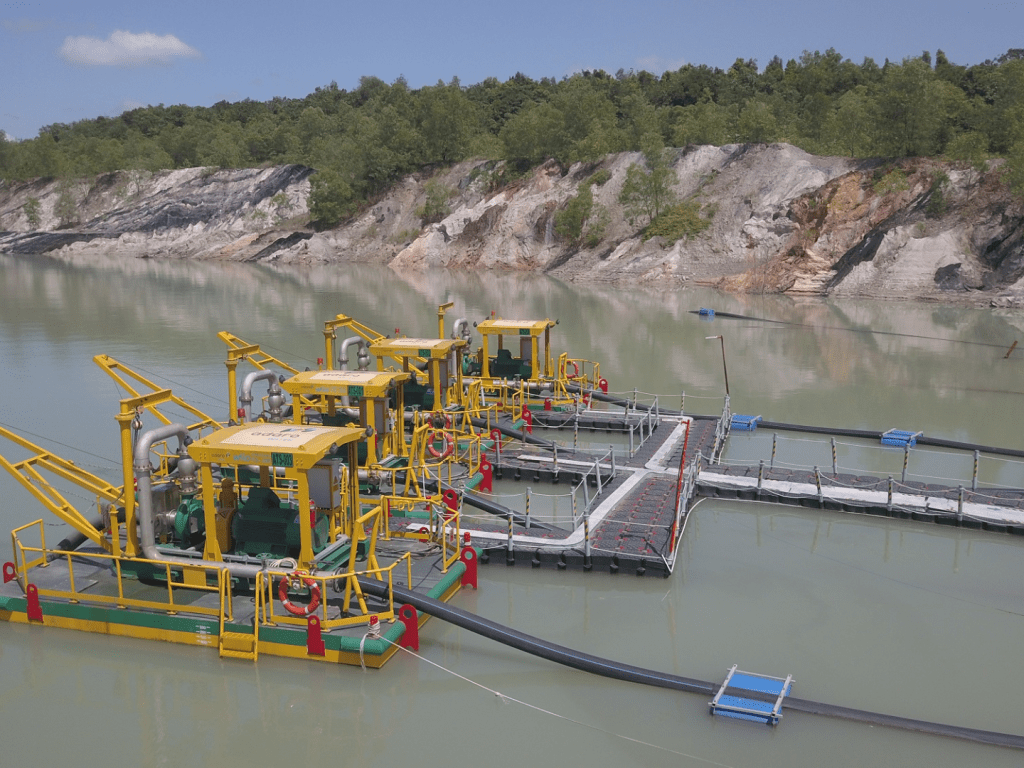

Wilo Indonesia has demonstrated a strong dedication to delivering comprehensive solutions for the mining industry, making headlines in 2021 and 2023 after securing a significant contract with Adaro Mining Group.

The Adaro Mining Group operates one of the largest coal mines in Indonesia, situated in Tanjung Tabalong, approximately 200 kilometres from Banjarmasin, the capital of South Kalimantan. The contractor, PT Adaro Tirta Sarana, had specific requirements for the coal mine, which included the pumping of 17 million cubic meters of water annually from Hill 11 Pit and 19 million cubic meters of water from Pit 1 Wara, addressing the challenges posed by substantial volumes of mud and acidic water.

ALSO READ:

Energy transition boosts mining beneficiation—who benefits?

To meet these demands, Wilo provided eight FD200EM c/w 355 kW pumpsets with Siemens motors, eight priming system sets with Atlas Copco vacuum pumps, eight Schneider VFD and automation monitoring systems, all as floatable units.

The FD (Force Dewatering) pumps, part of Wilo’s extensive range of mine dewatering solutions, can be operated using either electric motors or engine drivers, providing flexibility to accommodate different site conditions. Utilising an electric motor with a Variable Speed Drive (VSD) inverter enables the adjustment of pump speed based on load, enhancing energy efficiency.

A standout feature of the FD pump system is its integration of Internet of Things (IoT) technology, which allows for remote monitoring of pump performance. This capability offers a more cost-effective and time-efficient solution, along with comprehensive data recording, compared to traditional monitoring methods.

Wilo has also introduced a pay-per-use business model for its customers, driven by the increasing demand for mine dewatering services in response to rising international coal prices. By implementing this model, Wilo Indonesia, along with Wilo South Africa, seeks to optimise resource utilisation while providing affordable and efficient water management solutions to mining contractors.

Wilo is dedicated to advancing sustainability and innovation, positioning itself as a key contributor to the growth of the mining sector while upholding environmental stewardship. The company is focused on providing high-quality, sustainable solutions that address the changing demands of the mining industry.

For further details about our mine dewatering pumps and system solutions, please reach out to us at +27 11 608 2780 or email us at [email protected].