Following the deployment of US$25 million in mine finance by FSDEA (Fundo Soberano de Angola), Angola’s Sovereign Wealth Fund, Pensana has begun main construction activities on site.

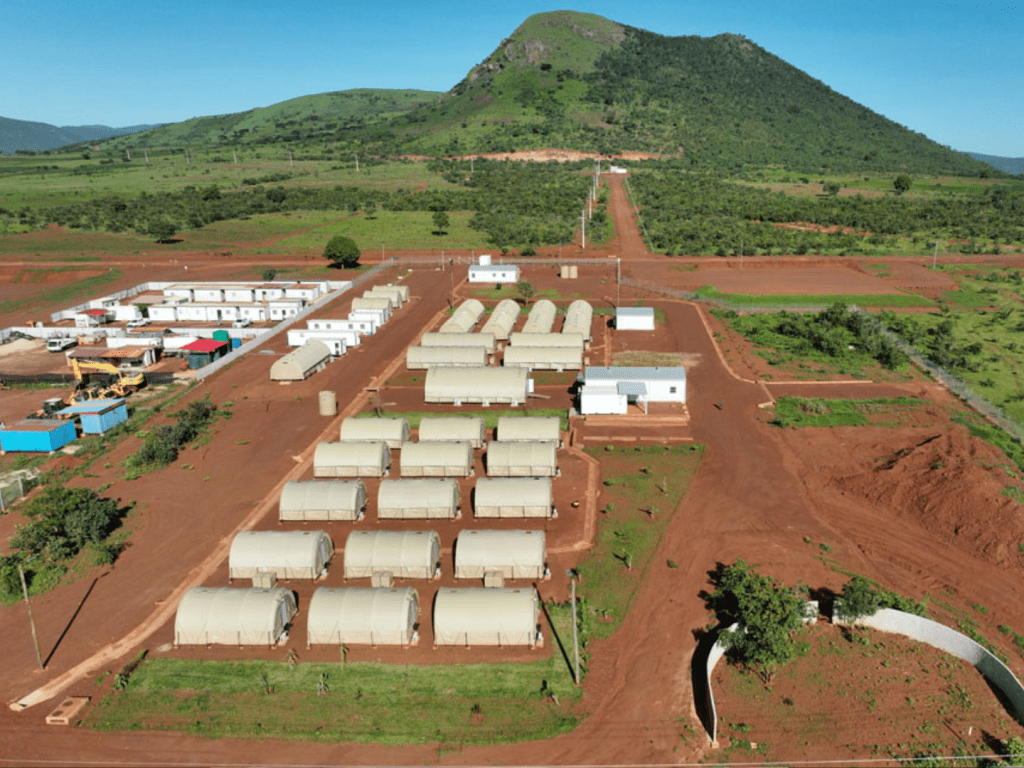

The project team, under the leadership of Project Director Kevin Botha, a South African project management professional with over 45 years’ experience has initiated the key procurement and engineering contracts. Engineering service providers, Pro-Process and ADP (Lycopodium RSA) have been formally appointed and have commenced activities. The preparatory site works completed earlier this year has enabled a streamlined construction program. The main contractor Grupo Nov has been mobilized and is expanding its workforce to over 100 on-site personnel with additional earth-moving equipment en-route to complete the terracing in the production plant area.

ALSO READ: Pensana gets US$3.4-million boost from US DFC for Angola projects

Tim George, Chief Executive Officer of Pensana, commented: “The commencement of main construction activities is a pivotal moment for the project which has been six years in the making. Early momentum has been established under the leadership of our on-site team headed by Country Manager Geraldine Tchimbali and Site Service Manager Benedito Dumbo and now with the engineering and construction teams mobilised we are looking forward to substantive progress over the coming weeks.”

Pensana has spent over US$70 million over the past six years on exploration, technical and environmental studies on the Longonjo rare earth project in the Huambo district of Angola approximately 350 kilometres Southeast of the capital Luanda. The Company has successfully delineated a near surface JORC compliant reserve of 22 million tonnes grading 3.04% TREO containing 139,457 tonnes of NdPrO making it one of the world’s largest and highest grade, undeveloped magnet metal rare earth deposits with a mine life of over 20 years. The electrification of motive power is arguably the biggest energy transition in history and needs rare earths for permanent magnets. Initial production will be 20,000 tonnes of a highly marketable clean MREC. A proposed second phase expansion will see production increase to 40,000 tonnes per annum of MREC representing around 5% of the world’s production capable of being converted into permanent magnets for electric vehicles and offshore wind turbines.