As underground mines venture deeper and become increasingly complex, ventilation and cooling systems are facing unprecedented challenges. To meet these demands, global leader in energy and industrial gas solutions Howden, a Chart Industries company is deploying a combination of advanced equipment, digital innovation, and expert engineering to ensure that deep-level mining operations remain safe, efficient and sustainable. STEPHAN BERGH, Mining Lead for Africa, the Middle East, and India at Howden, speaks to PENELOPE MASILELA about the company’s innovations.

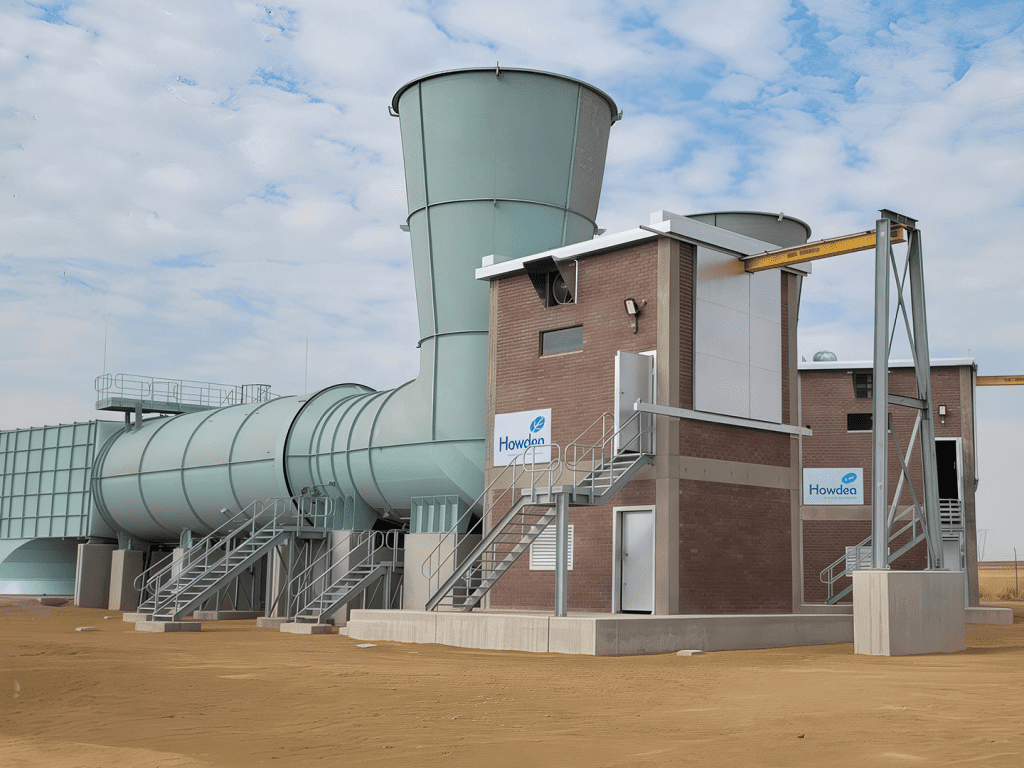

Howden, with more than 170+ years of engineering legacy, focuses on providing intelligent and adaptable solutions for demanding underground mining environments. With local service teams in over 50 countries, the company leverages a global support network to tailor solutions to sitespecific needs. Bergh explains, “We focus on delivering intelligent, adaptable, and sustainable solutions to the world’s most demanding underground mining operations.”

Smarter ventilation for safer, deeper mining

Howden’s underground mining solutions draw from a global network of engineering expertise, allowing for tailored designs that reflect each mine’s unique ventilation requirements. Their innovations include a range of high-efficiency fans and air handling systems built to deliver consistent airflow while keeping energy consumption in check. This is especially critical as underground mines extend deeper, which leads to an increase in system resistance that impacts the operational duty of the equipment and subsequently, energy consumption.

Bergh says cooling is equally vital in deep underground mines. Howden addresses this with state-of-the-art technologies such as surface bulk air coolers (BACs), ice plants, and advanced refrigeration systems. “These systems are designed to deliver effective cooling to deep working areas, were traditional systems can no longer keep up. Ice cooling, in particular for ultra-deep level operations, is becoming a preferred alternative, offering lower pumping costs and greater thermal efficiency.

ALSO READ:

Howden Technology Day 2025 unveils innovations in mining

“As mines expand and deepen, the heat load imposed on the workings also increases due to factors such as auto-compression and higher virgin rock temperatures,” explains Bergh. “In ultradeep level mines, conventional cooling systems are reaching their limits, which is why we’re advancing technologies like ice plants to make ultra-deep level mining more sustainable,” adds Bergh.

Digital tools that adapt to underground conditions

To meet the ever-changing conditions underground, Howden incorporates automation and digitalisation across its systems. Mining operations are dynamic in nature, with ventilation and cooling demands fluctuating daily. Through its Ventsim™ CONTROL platform, Howden enables real-time monitoring and autonomous control of ventilation equipment. This allows systems to adjust airflow and cooling output according to operational needs—improving worker safety, optimising resource use, and significantly reducing operational costs.

“Where automation gives you flexible equipment operation, digitisation provides the real-time information necessary to make informed decisions,” Bergh explains. “Ventsim™ CONTROL allows users to remotely and autonomously manage ventilation devices, matching output to the mine’s immediate demand.” He further says for underground mines operating at ultra-deep levels, Howden’s technology is a game changer.

“We are the market leader in large centrifugal fans, ammoniabased refrigeration systems, and ultra-cold ice plants—capable of handling the extreme pressures and cooling demands found in some of the deepest mines on Earth. One of the most transformative developments has been the Ventilation on Demand (VoD) systems, which ensures air and cooling are directed precisely where needed, rather than wasting energy on unnecessary circulation,” Bergh says.

“We are currently working with several deep level mines to deploy VoD systems that efficiently utilise and direct available ventilation and cooling to critical working areas. This directly improves working conditions and supports operational efficiency.”

A sustainable path to the future of mining

Cost efficiency is another priority for underground operators. Howden’s approach factors in total cost of ownership, offering robust and bespoke systems backed by long-term service agreements to ensure performance over the asset’s lifecycle. “This helps customers manage budgets while staying compliant with safety standards and occupational environmental regulations,” states Bergh.

Howden is exploring the next frontier in underground cooling—cryogenic technology. As part of Chart Industries, the global leader in cryogenics, Howden is uniquely positioned to develop alternative cooling methods for the mines of the future. Although cryogenic cooling is still in its infancy within mining, it represents a bold step beyond conventional systems.

“The mines of the future will be more intelligent and more adaptable to changing operational needs. Our response is to continue developing digital and automated systems, incorporating machine learning for predictive control that can react and adjust to the mine’s dynamic conditions,” Bergh concludes.